Plasma Table Water Treatment

Plasma table water treatment. His company offers fluid that treats the water in CNC plasma tables. Greencut Plasma Cutting Water Table Treatment GreenCut Plasma Cutting Misting Fluid is a CNC plasma cutting water table treatment preventing corrosion and bacteria. The water also is used to capture.

This is very similar to Plasma Quench but you purchase and mix a few chemicals. PLASMA QUENCH RECIPE Heres the recipe for home-made PlasmaQuench 14 pound of sodium nitrite powder 15pound 1 teaspoon of Physan 20 88oz bottle 1 oz Ultramarine blue food-grade dye 5oz Mix well treats 75 gallons of water. You can often just look at plasma cut parts and determine visually if they were cut on a water table or a downdraft.

Water will splash around some. Industrial Drain with Water Table Purchase. The idea is to use the water to keep the material being cut cool during the cut process which helps to reduce warping and distortion in thin or highly detailed pieces.

The use of a water table in plasma serves a few purposes. Remote indirect and direct. Direct place the machine on plate 15003000mm cutting table with water table takes 16mm mild steel plate and 35mm when seam welded for metalwise lite cnc cutting machine.

Immediately biodegrades tramp oils that wash into the water table from the plasma cut metal sheet. Mine is great at keeping the black smog out of the air. Plasma Quench Home Brew.

For me this was a complete disaster Rusting started on the slats immediately and and spread to the sheets. Each Water Table will include a Welded Pan with Water Test Welded Slate Brackets Ladder Frame Bracing Added water table isolation diode technology and Plasma Defense water treatment. When CNC plasma cutting there are a lot of good reasons for using a water table instead of a dry or down draft table.

There will be a blue haze around the downdraft cut parts edges from the extra heat the metal experiences. But one common objection to plasma cutting mild steel on a.

Plasma Table Water Treatment Water treatment will reduce corrosion and improve safety.

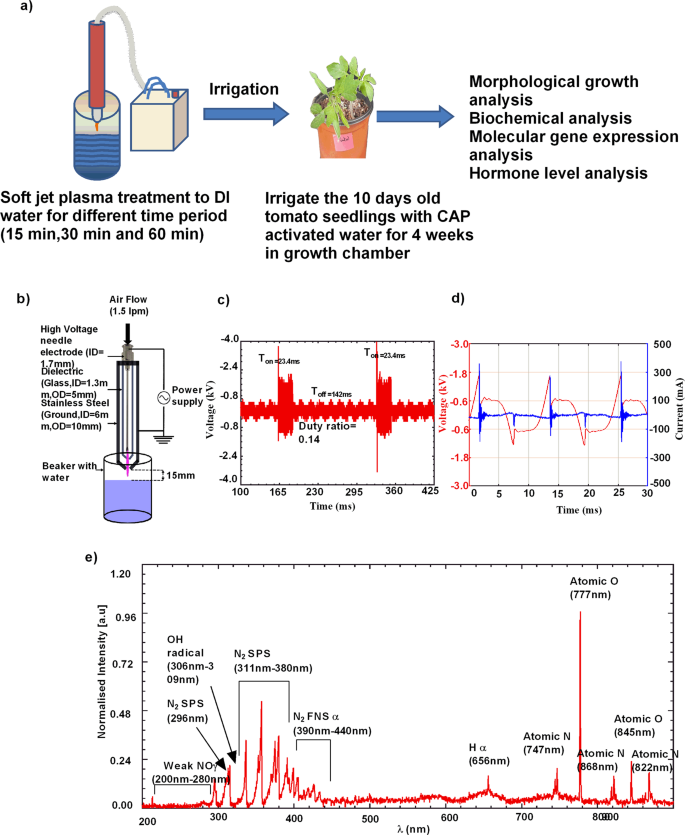

Plasma Soup - CNC Plasma Table Update - Water Tray Level - YouTube. Water will splash around some. Also a high performance safe biodegradable coolant used in machining cutting grinding drilling and tapping of all metals. Three categories of plasma treatment technologies exist including. Immediately biodegrades tramp oils that wash into the water table from the plasma cut metal sheet. Get Cnc Plasma Table Water TreatmentHave a question about our plasma cutting tables or our company. The use of a water table in plasma serves a few purposes. When CNC plasma cutting there are a lot of good reasons for using a water table instead of a dry or down draft table. But one common objection to plasma cutting mild steel on a.

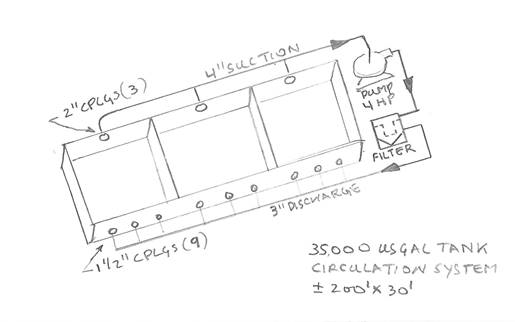

Our target should be to consolidate and enhance the top quality and service of current goods in the meantime frequently create new products to satisfy diverse customers calls for for Cnc Plasma Table Water Treatment We taking advantage of experience workmanship scientific administration and advanced equipment ensure the product quality of production we not only win the customers faith. To further process the plate for painting or. But you do not have the added noise of a fan or that added energy consumption that you would have with a downdraft system. A water table is less expensive to purchase does not require a dust collector in most areas reduces noise eliminates dangerous arc flash reduces heat distortion and keeps parts cool just to name a few. The water also is used to capture. Our target should be to consolidate and enhance the top quality and service of current goods in the meantime frequently create new products to satisfy diverse customers calls for for Cnc Plasma Table Water Treatment We taking advantage of experience workmanship scientific administration and advanced equipment ensure the product quality of production we not only win the customers faith. With a water table your using a contained bed.

Post a Comment for "Plasma Table Water Treatment"